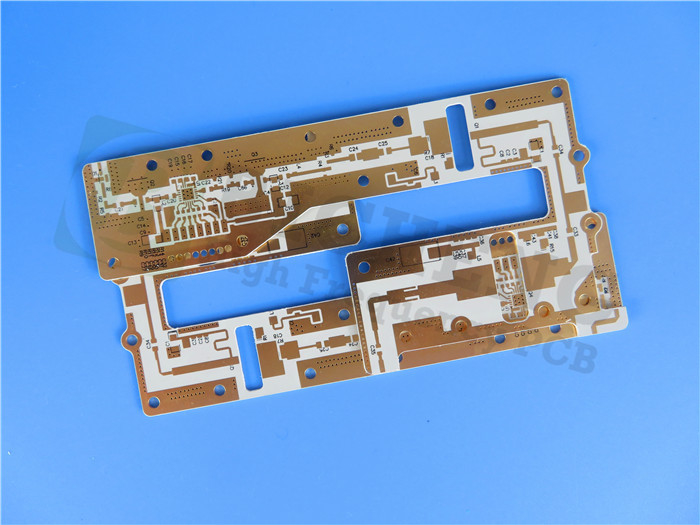

TSM-DS3 High Frequency Printed Circuit Board

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Material Introduction

TSM-DS3 is an exceptional thermally stable material that boasts industry-leading low loss properties with a dissipation factor (DF) of 0.0011 at 10 GHz. It offers the predictability and consistency comparable to the best fiberglass reinforced epoxies available in the market.

TSM-DS3 stands out as a ceramic-filled reinforced material with a remarkably low fiberglass content of approximately 5%. This unique composition allows it to rival epoxies in fabricating large format complex multilayers, making it an ideal choice for demanding applications.

One of the key highlights of TSM-DS3 is its suitability for high power applications. With a high thermal conductivity (TC) of 0.65 W/m*K, this material efficiently conducts heat away from other heat sources in a printed wiring board (PWB) design. This capability ensures effective heat dissipation and helps maintain optimal performance in high-power scenarios.

Moreover, TSM-DS3 has been developed to exhibit very low coefficients of thermal expansion, making it highly suitable for applications that undergo demanding thermal cycling. This exceptional feature enhances the material's performance and reliability, providing stability even in environments with significant temperature variations.

Features

1.TSM-DS3 offers an industry-leading dissipation factor (DF) of 0.0011 at 10GHz

2. With high thermal conductivity, TSM-DS3 effectively conducts heat away from heat sources.

3.The material has a low fiberglass content of approximately 5%.

4.TSM-DS3 exhibits dimensional stability comparable to epoxy materials.

5. It enables the fabrication of large format, high layer count printed wiring boards (PWBs) with complex designs.

6. The material allows for the successful construction of complex PCBs with high yield and consistent performance.

7. TSM-DS3 maintains stable dielectric constant (DK) within +/- 0.25 across a wide temperature range (-30 °C to 120 °C).

8. It is compatible with resistor foils, expanding its range of applications.

Typical Applications

TSM-DS3 finds application in various fields, including:

1. Couplers

- Phased Array Antennas

- Radar Manifolds

- mmWave Antennas

- Oil Drilling

- Semiconductor / Automatic Test Equipment (ATE) Testing

Our PCB Capability (TSM-DS3)

| PCB Capability (TSM-DS3) |

| PCB Material: |

Ceramic-filled Woven Fiberglass PTFE Laminates |

| Designation: |

TSM-DS3 |

| Dielectric constant: |

3 +/-0.05 |

| Dissipation factor |

0.0011 |

| Layer count: |

Single Sided, Double Sided, Multi-layer PCB, Hybrid PCB |

| Copper weight: |

1oz (35µm), 2oz (70µm) |

| Dielectric thickness |

5mil (0.127mm), 10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm), 90mil (2.286mm) |

| PCB size: |

≤400mm X 500mm |

| Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

| Surface finish: |

Immersion gold, HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold etc.. |

TSM-DS3 Typical Values

| Property |

Test Method |

Unit |

TSM-DS3 |

Unit |

TSM-DS3 |

| Dk |

IPC-650 2.5.5.3 |

|

3.00 |

|

3.00 |

| TcK (-30 to 120 °C) |

IPC-650 2.5.5.5.1 (Modified) |

ppm |

5.4 |

ppm |

5.4 |

| Df |

IPC-650 2.5.5.5.1 (Modified) |

|

0.0011 |

|

0.0011 |

| Dielectric Breakdown |

IPC-650 2.5.6 (ASTM D 149) |

kV |

47.5 |

kV |

47.5 |

| Dielectric Strength |

ASTM D 149 (Through Plane) |

V/mil |

548 |

V/mm |

21,575 |

| Arc Resistance |

IPC-650 2.5.1 |

Seconds |

226 |

Seconds |

226 |

| Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.07 |

% |

0.07 |

| Flexural Strength (MD) |

ASTM D 790/ IPC-650 2.4.4 |

psi |

11,811 |

N/mm2 |

81 |

| Flexural Strength (CD) |

ASTM D 790/ IPC-650 2.4.4 |

psi |

7,512 |

N/mm2 |

51 |

| Tensile Strength (MD) |

ASTM D 3039/IPC-650 2.4.19 |

psi |

7,030 |

N/mm2 |

48 |

| Tensile Strength (CD) |

ASTM D 3039/IPC-650 2.4.19 |

psi |

3,830 |

N/mm2 |

26 |

| Elongation at Break (MD) |

ASTM D 3039/IPC-650 2.4.19 |

% |

1.6 |

% |

1.6 |

| Elongation at Break (CD) |

ASTM D 3039/IPC-650 2.4.19 |

% |

1.5 |

% |

1.5 |

| Young’s Modulus (MD) |

ASTM D 3039/IPC-650 2.4.19 |

psi |

973,000 |

N/mm2 |

6,708 |

| Young’s Modulus (CD) |

ASTM D 3039/IPC-650 2.4.19 |

psi |

984,000 |

N/mm2 |

6,784 |

| Poisson’s Ratio (MD) |

ASTM D 3039/IPC-650 2.4.19 |

|

0.24 |

|

0.24 |

| Poisson’s Ratio (CD) |

ASTM D 3039/IPC-650 2.4.19 |

|

0.20 |

|

0.20 |

| Compressive Modulus |

ASTM D 695 (23.C) |

psi |

310,000 |

N/mm2 |

2,137 |

| Flexural Modulus (MD) |

ASTM D 790/IPC-650 2.4.4 |

kpsi |

1,860 |

N/mm2 |

12,824 |

| Flexural Modulus (CD) |

ASTM D 790/IPC-650 2.4.4 |

kpsi |

1,740 |

N/mm2 |

11,996 |

| Peel Strength (CV1) |

IPC-650 2.4.8 Sec 5.2.2 (TS) |

lbs/in |

8 |

N/mm |

1.46 |

| Thermal Conductivity (unclad) |

ASTM F 433/ASTM 1530-06 |

W/M*K |

0.65 |

W/M*K |

0.65 |

| Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in. |

0.21 |

mm/M |

0.21 |

| Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in. |

0.20 |

mm/M |

0.20 |

| Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.5 (TS) |

mils/in. |

0.15 |

mm/M |

0.15 |

| Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.5 (TS) |

mils/in. |

0.10 |

mm/M |

0.10 |

| Surface Resistivity |

IPC-650 2.5.17.1 Sec. 5.2.1 (ET) |

Mohms |

2.3 x 10^6 |

Mohms |

2.3 x 10^6 |

| Surface Resistivity |

IPC-650 2.5.17.1 Sec. 5.2.1 (HC) |

Mohms |

2.1 x 10^7 |

Mohms |

2.1 x 10^7 |

| Volume Resistivity |

IPC-650 2.5.17.1 Sec. 5.2.1 (ET) |

Mohms/cm |

1.1 x 10^7 |

Mohms/cm |

1.1 x 10^7 |

| Volume Resistivity |

IPC-650 2.5.17.1 Sec. 5.2.1 (HC) |

Mohms/cm |

1.8 x 10^8 |

Mohms/cm |

1.8 x 10^8 |

| CTE (x axis) (RT to 125ºC) |

IPC-650 2.4.41/TMA |

ppm/ºC |

10 |

ppm/ºC |

10 |

| CTE (y axis) (RT to 125ºC) |

IPC-650 2.4.41/TMA |

ppm/ºC |

16 |

ppm/ºC |

16 |

| CTE (z axis) (RT to 125ºC) |

IPC-650 2.4.41/TMA |

ppm/ºC |

23 |

ppm/ºC |

23 |

| Density (Specific Gravity) |

ASTM D 792 |

g/cm3 |

2.11 |

g/cm3 |

2.11 |

| Hardness |

ASTM D 2240 (Shore D) |

|

79 |

|

79 |

| Td (2% Weight Loss) |

IPC-650 2.4.24.6 (TGA) |

ºC |

526 |

ºC |

526 |

| Td (5% Weight Loss) |

IPC-650 2.4.24.6 (TGA) |

ºC |

551 |

ºC |

551 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!