Discover the unmatched reliability and quality of the new PCB from Bicheng Limited

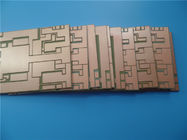

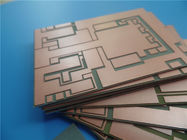

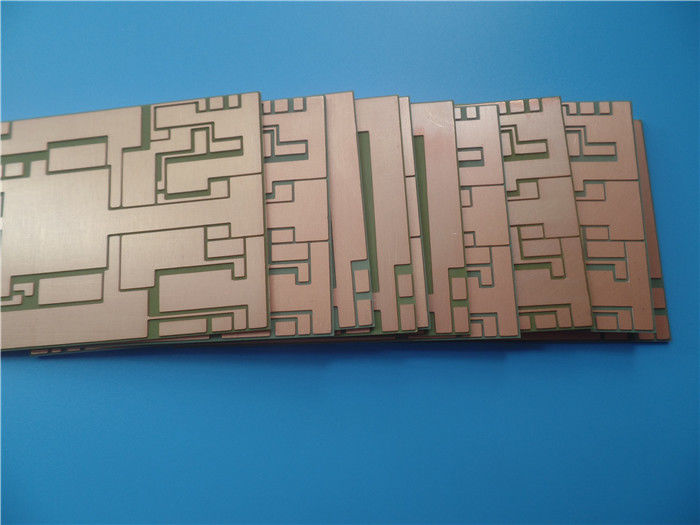

Bicheng Limited has launched a new Printed Circuit Board (PCB) with advanced features that cater to the needs of the modern electronic industry. This multilayer 4-layer board has a base copper of 35um and a Polyimide Core of 0.508mm. The finished board thickness is 1.8mm, and the finished Cu weight is 1.0oz (1.4 mils) on all layers. The Via plating thickness is 1mil, and the surface finish is Electroless Nickle and Immersion Gold (ENIG). It has a board dimension of 186mm x 76mm with a tolerance of +/- 0.15mm and can operate in temperatures ranging from -40℃ to +85℃.

The PCB material used, Polyimide Tg250 ℃ High Temperature High Frequency Material, provides high-temperature resistance, making it suitable for high-temperature applications. The manufacturing process is lead-free, making it an eco-friendly option. The board undergoes 100% electrical testing, ensuring high reliability and quality.

The PCB has advanced features such as slotted holes, non-plated holes for breakouts, and an ENIG surface finish. It has 372 components, 435 pads, 151 Thru Hole Pads, 132 Top SMT Pads, 152 Bottom SMT Pads, 192 vias, and 58 nets. The slotted holes defined as per Gerber are to be plated through, and the side-by-side holes define the dimensions of the slots. All edges are tab-routed, and non-plated holes for breakouts are included in Gerbers, with breakouts shown as per design FabDrawing.

The new PCB from Bicheng Limited has several benefits, including high-temperature resistance, an eco-friendly manufacturing process, high reliability and quality, and advanced features. It has applications in aerospace, automotive, medical, and military fields.

In conclusion, Bicheng Limited has once again demonstrated their commitment to delivering high-quality and innovative products that meet the demands of the electronic industry. The new PCB is a cutting-edge product that offers advanced features and benefits, making it suitable for a wide range of applications.

Polyimide Tg250 ℃ PCB: The Key to Reliable and Efficient High Temperature Electronics with

------Benefits and Advantages of the New PCB

What is Polyimide Tg250 ℃ Material and Why It Matters?

Polyimide Tg250 ℃ is a high-performance polymer that can withstand temperatures up to 250 degrees Celsius. It is a thermosetting plastic that is widely used in advanced electronics applications due to its high temperature resistance and excellent dielectric properties. Polyimide Tg250 ℃ material can be made into various forms, including films, coatings, and adhesives, making it highly versatile and adaptable to different manufacturing processes. The material has gained significant attention in the electronics industry due to its exceptional properties and potential applications.

Properties and Characteristics of Polyimide Tg250 ℃ Material

Polyimide Tg250 ℃ material has several key properties that make it ideal for high-temperature and high-frequency applications. Its high glass transition temperature (Tg) of 250 degrees Celsius allows it to remain stable and retain its properties even at extremely high temperatures. Additionally, it has excellent electrical insulation properties, making it an ideal material for electronic components that require isolation from electrical currents. Polyimide Tg250 ℃ material also has a low coefficient of thermal expansion, meaning it does not expand or contract significantly when exposed to changes in temperature.

Advantages of Polyimide Tg250 ℃ Material in Electronic Manufacturing

Polyimide Tg250 ℃ material offers several advantages over other high-temperature materials such as ceramics and metals. It is lightweight, flexible, and can be easily molded into different shapes, making it ideal for use in complex electronic components. Additionally, it has high resistance to chemical and environmental degradation, making it suitable for use in harsh environments. Polyimide Tg250 ℃ material also has excellent thermal stability, enabling electronic components to operate reliably at high temperatures without degradation.

Applications of Polyimide Tg250 ℃ Material in High Temperature and High Frequency Electronics

Polyimide Tg250 ℃ material has a wide range of potential applications in high-temperature and high-frequency electronics. It can be used in the manufacturing of sensors, microprocessors, and other electronic components that require high temperature resistance and stability. Additionally, it can be used in the production of flexible circuits and antennas for use in wearable technology, medical devices, and aerospace applications. Polyimide Tg250 ℃ material can also be used in the production of insulators and adhesives for electronic components.

Polyimide Tg250 ℃ Material vs Other High Temperature and High Frequency Materials: A Comparative Analysis

Compared to other high-temperature and high-frequency materials such as ceramics and metals, Polyimide Tg250 ℃ material offers several advantages. It is more flexible and lightweight, making it easier to work with and more adaptable to different manufacturing processes. It also has higher resistance to chemical and environmental degradation, making it more suitable for use in harsh environments. Additionally, it has higher resistance to thermal shock and cycling, making it more reliable over time.

How Polyimide Tg250 ℃ Material Improves Reliability and Efficiency in High-Temperature Electronics

Polyimide Tg250 ℃ material's high temperature resistance and stability make it an ideal material for improving the reliability and efficiency of high-temperature electronics. By using Polyimide Tg250 ℃ material, manufacturers can create electronic components that can operate at higher temperatures without degradation, resulting in more efficientand reliable performance. This can lead to improved product lifetimes and reduced maintenance costs for electronic devices operating in extreme environments.

Manufacturing and Processing Techniques for Polyimide Tg250 ℃ Material

Polyimide Tg250 ℃ material can be manufactured and processed using various techniques, including film casting, hot pressing, and injection molding. The material can also be coated onto other substrates or used as an adhesive in electronic components. The manufacturing and processing techniques used for Polyimide Tg250 ℃ material depend on the specific application and the desired properties of the final product.

Challenges and Limitations of Using Polyimide Tg250 ℃ Material in Electronics

While Polyimide Tg250 ℃ material offers many advantages for high-temperature and high-frequency electronics applications, there are also some challenges and limitations to consider. One of the main challenges is the cost of the material, which is higher than other materials commonly used in electronics. Additionally, the material is more difficult to process than some other materials, requiring specialized equipment and techniques. Finally, the material's high temperature resistance may not be necessary for all electronic components, making it less suitable for certain applications.

Future Developments and Potential Applications of Polyimide Tg250 ℃ Material

Polyimide Tg250 ℃ material is a rapidly evolving field, with ongoing research and development aimed at improving its properties and expanding its potential applications. One area of particular interest is the use of Polyimide Tg250 ℃ material in 5G and other high-frequency communication technologies. Additionally, there is ongoing research into using the material in biomedical applications, such as implantable medical devices and sensors.

Conclusion: The Promising Role of Polyimide Tg250 ℃ Material in the Future of High-Temperature Electronics

In conclusion, Polyimide Tg250 ℃ material is a game-changing material for high-temperature and high-frequency electronics applications. Its exceptional properties, versatility, and potential applications make it a promising material for use in advanced electronics components. While there are some challenges and limitations to consider, ongoing research and development are expanding the potential uses of Polyimide Tg250 ℃ material and improving its properties. As the demand for high-temperature and high-frequency electronics continues to grow, Polyimide Tg250 ℃ material will undoubtedly play an increasingly important role in the future of electronic manufacturing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!