Comparative Analysis: RO4003C and FR-4 (IT-180A) Laminates for High-Performance PCBs

The selection of laminate materials greatly influences the performance and reliability of high-performance PCBs. In this article, we will explore the features, stack-up configurations, construction details, and typical applications of two popular laminates: RO4003C and FR-4 (IT-180A). Our aim is to present a balanced analysis of their advantages, disadvantages, and unique characteristics, assisting engineers in making well-informed decisions tailored to their specific PCB requirements.

RO4003C Profile

Rogers Corporation offers the RO4003C laminate, a hydrocarbon ceramic woven glass material. This cost-effective alternative to conventional microwave laminates delivers excellent electrical performance. With a dielectric constant (DK) of 3.38 at 10 GHz and a dissipation factor of 0.0027 at 10 GHz, RO4003C ensures precise control over signal integrity and minimal loss. Its high glass transition temperature (Tg) exceeding 280 °C and decomposition temperature (Td) above 425 °C make it suitable for demanding thermal environments.

Advantages:

- Precise control over dielectric constant and low loss

- Cost-effective compared to conventional microwave laminates

- High Tg and decomposition temperature for thermal reliability

Disadvantages:

- Non-brominated material, not UL 94 V-0 rated

FR-4 (IT-180A) Profile

ITEQ's FR-4 (IT-180A) is a high-thermal-reliability laminate. This epoxy glass material possesses a high glass transition temperature (Tg) of over 175 °C, ensuring exceptional heat resistance and reliable performance in through-hole applications. With a DK of 4.4 at 1 GHz and a dissipation factor of 0.015 at 1 GHz, FR-4 (IT-180A) provides reliable electrical performance for a wide range of applications.

Advantages:

- Excellent resistance to CAF (Conductive Anodic Filamentation)

- Compatible with lead-free processes

- High heat resistance and reliable through-hole performance

- Excellent mechanical processability

Disadvantages:

- Relatively higher dissipation factor compared to RO4003C

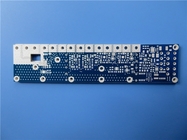

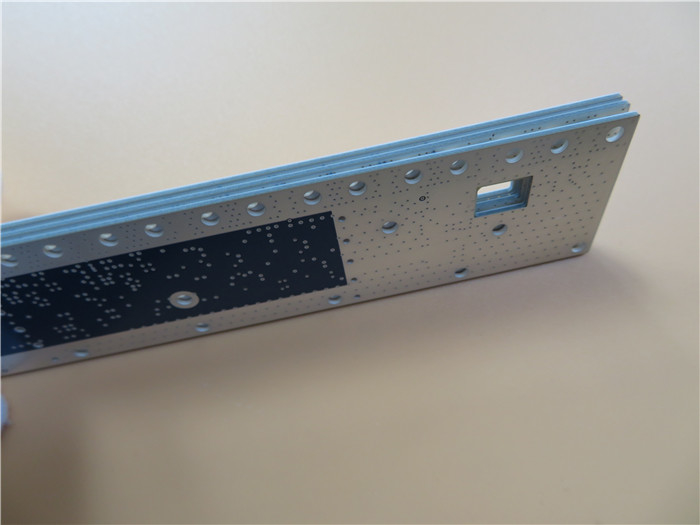

Stack-Up Configuration and Construction Details

For a 6-layer rigid PCB, the stack-up configuration using these laminates is as follows:

- Copper_layer_1 - 35 μm (1oz)

- Rogers 4003C Core - 12mil (0.305mm)

- Copper_layer_2 - 35 μm (1oz)

- Prepreg - 0.1mm

- Copper_layer_3 - 35μm (1oz)

- Core IT-180A FR-4

- Copper_layer_4 - 35μm (1oz)

- Prepreg - 0.1mm

- Copper_layer_5 - 35 μm (1oz)

- Rogers 4003C Core - 12mil (0.305mm)

- Copper_layer_6 - 35 μm (1oz)

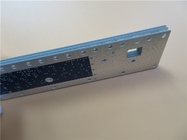

Construction details include a board dimension of 57mm x 57mm with a tolerance of +/- 0.15mm. The minimum trace/space requirement is 4/5 mils, and the minimum hole size is 0.3mm with via filling and capping. The finished board thickness is 1.1mm with a finished copper weight of 1oz (1.4 mils) on each layer. The via plating thickness is 25 μm, and the surface finish is immersion gold (ENIG). The top and bottom silkscreens are in white, and the solder mask is in matt blue. The PCB undergoes 100% electrical testing before shipment, ensuring adherence to high-quality standards.

PCB Statistics and Artwork Standard

The PCB based on these laminates comprises 28 components and 68 pads, including 32 thru-hole pads, 21 top SMT pads, and 15 bottom SMT pads. With 73 vias and 6 nets, it offers versatility for various circuit requirements. The artwork supplied follows the Gerber RS-274-X format, facilitating seamless integration into the manufacturing process. The laminates conform to the IPC-Class-2 quality standard, ensuring reliable performance and adherence to industry benchmarks.

Typical Applications and Global Availability

RO4003C and FR-4 (IT-180A) laminates find applications in several industries. RO4003C is commonly used in cellular base station antennas, power amplifiers, RF identification tags, automotive radar, sensors, and LNBs for direct broadcast satellites. FR-4 (IT-180A) is suitable for numerous applications requiring excellent CAF resistance, lead-free compatibility, high heat resistance, and reliable through-hole performance.

Availability:

Both laminates are widely available worldwide, ensuring easy accessibility for PCB manufacturersand designers.

The selection of the right laminate material is crucial for achieving optimal performance and reliability in high-performance PCBs. RO4003C and FR-4 (IT-180A) laminates offer distinct advantages and unique characteristics. RO4003C provides precise control over dielectric constant and low loss while offering cost-effective solutions. FR-4 (IT-180A) excels in CAF resistance, lead-free compatibility, high heat resistance, and reliable through-hole performance. Understanding their features and applications empowers engineers to make well-informed decisions when designing PCBs for various industries and applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!