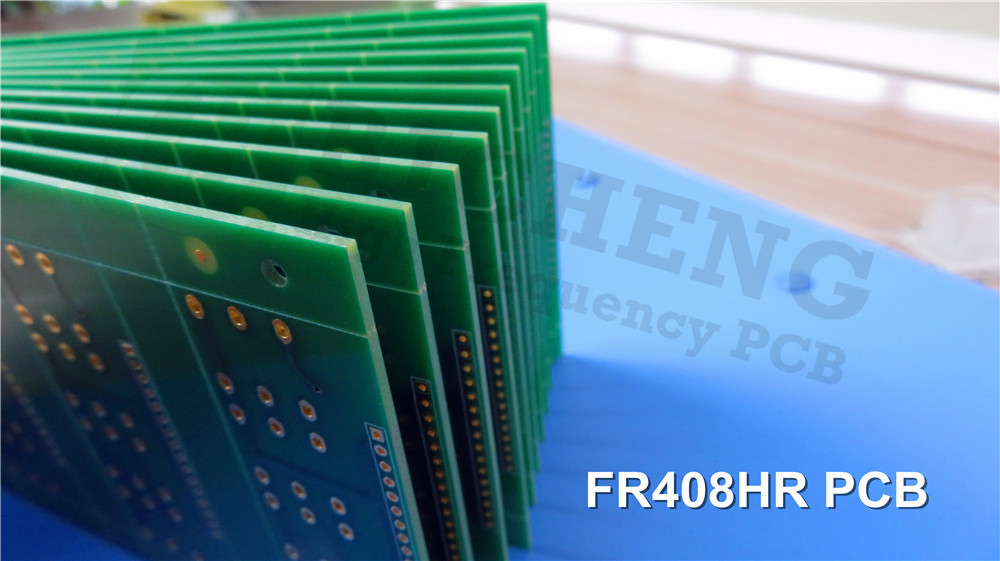

Introducing FR408HR: Unleashing Unparalleled Performance for Multilayer PCB Applications

When it comes to pushing the boundaries of multilayer PCB applications, one resin system stands head and shoulders above the rest: FR408HR. Developed by the visionary minds at Isola, FR408HR is the epitome of high-performance FR-4 resin systems. With its exceptional thermal capabilities and unwavering reliability, FR408HR reigns supreme in the realm of demanding electronic designs. Join us as we embark on a journey through the remarkable features, exclusive benefits, and captivating applications of FR408HR, a true champion in the cutthroat world of PCBs.

Engineered for Excellence:

FR408HR flaunts a host of cutting-edge features that set it apart from the competition:

1. Electrifying Electrical Performance:

- Unleashing a Dk (Dielectric Constant) of 3.65 at 10GHz, FR408HR ensures lightning-fast signal transmission.

- With a minuscule dissipation factor of 0.0095 at 10GHz, this resin system minimizes energy loss, resulting in superior efficiency.

- Boasting 25% more electrical bandwidth (lower loss) than its rivals, FR408HR propels your designs to new heights.

- Harmonious coefficient of thermal expansion (CTE) matched to copper guarantees seamless integration and enhanced reliability.

2. Thermal Prowess at Its Core:

- With an impressive glass transition temperature (Tg) of 190°C, FR408HR fearlessly endures scorching conditions.

- Safeguarded by a robust Decomposition Temperature (Td) of 360°C, this resin system withstands the harshest environments with unwavering resilience.

- T260 >60 min and T288 >30 min ensure that FR408HR remains unyielding in the face of extreme heat, offering peace of mind.

3. Reliability Redefined:

- FR408HR embraces the future with open arms, facilitating lead-free assembly compatibility.

- Unlock the potential of your designs with via filling capability, enhancing signal integrity and unleashing unparalleled performance.

- Bid farewell to worries of conductivity issues as FR408HR triumphs over CAF, extending the lifespan of your creations.

- Embrace flexibility with multiple lamination cycles, empowering manufacturers and unleashing creativity.

4. Compliance and Moisture Resistance:

- FR408HR proudly holds the RoHS compliant badge, exemplifying its commitment to environmental responsibility.

- Its superior moisture resistance during reflow processes ensures uncompromised performance, even in the face of atmospheric challenges.

Building Brilliance: PCB Stackup and Construction Details:

FR408HR harmonizes effortlessly with diverse PCB designs. Behold a tantalizing glimpse into a 4-layer rigid PCB stackup utilizing FR408HR:

- Ascend to the heavens with a top layer of 35 μm copper, your gateway to exceptional conductivity.

- The 152 μm prepreg layer stands as the bridge to greatness, unfaltering in its support.

- Inner Layer 1, fortified by a 35 μm copper foundation, adds strength to your architectural marvel.

- The FR408HR Core, standing tall at 1.535 mm, forms the bedrock of your creation, ensuring steadfastness.

- Inner Layer 2, mirroring its predecessor, fortifies the structural integrity of your design with a 35 μm copper layer.

- The 152 μm prepreg layer provides unwavering support, connecting the dots of your masterpiece.

- The bottom layer, crowned with 35 μm copper, completes the symphony, delivering the final touch of conductivity.

Quality and Precision Woven Together:

At the heart of our construction lies an unwavering commitment to quality:

- Immerse yourself in a realm of precision with board dimensions of 170mm x 130mm, boasting a tolerance of +/- 0.15mm.

- Witness the magic of minuscule traces and spaces, with a minimum requirement of 4/5 mils, highlighting meticulous attention to detail.

- Delve into the depths of the extraordinary with a minimum hole size of 0.3mm, showcasing the limitless possibilities that await.

- Experience the innovation of blind vias, a testament to our dedication to pushing boundaries.

- Revel in the splendor of a finished board thickness of 2.0mm, ensuring both robustness and elegance.

- With a finished copper weight of 1oz (1.4 mils) on the outer layers, conductivity reigns supreme.

- Via plating thickness of 20 μm instills confidence in the longevity of your creation.

- Bask in the radiance of an immersion gold surface finish, a testament to both beauty and functionality.

- The top silkscreen, dressed in immaculate white, adds a touch of sophistication to your design.

- The bottom silkscreen, absent yet present, allows your creation to speak for itself.

- Adorned with red solder masks onboth the top and bottom layers, your design exudes a captivating aura.

- Filled and capped vias, employing via-in-pad technology, ensure unrivaled reliability, leaving no room for compromise.

- Our commitment to excellence is unwavering, as each board undergoes 100% electrical testing before it leaves our facility.

Statistics that Speak Volumes:

Let the numbers paint a picture of the grandeur that awaits:

- Witness the symphony of components, with a staggering 270 elements converging to create a masterpiece.

- Delve into the intricacy of our creation, boasting a total of 320 pads, each serving a purpose.

- Traverse the landscape of possibilities with 150 dedicated thru-hole pads, ready to be explored.

- Immerse yourself in the realm of SMT with 99 top SMT pads, beckoning you to unleash your creativity.

- Descend into the depths of innovation, where 71 bottom SMT pads pave the way for groundbreaking designs.

- Traverse the interconnections of your creation with 78 vias, each a testament to the harmonious collaboration of art and science.

- Marvel at the complexity of your design as 6 nets intertwine, fueling the symphony of connectivity.

Accessibility and Global Reach:

FR408HR's siren call echoes across continents, ensuring that its brilliance is within reach, no matter where you are in the world. Its global availability empowers designers and manufacturers to embark on a journey of unrivaled innovation, transcending borders and boundaries.

Unleash the Potential: Captivating Applications:

FR408HR finds its place in the hearts of various industries, leaving an indelible mark of excellence:

- Consumer Electronics: Ignite the imaginations of consumers with cutting-edge devices that deliver uncompromising performance and reliability.

- Servers and Workstations: Empower the digital landscape with powerful computing systems that push the boundaries of speed and efficiency.

- Automotive Electronics: Embark on a journey into the future of mobility, where FR408HR ensures the reliability and performance of critical automotive systems.

In Conclusion:

FR408HR stands as a testament to the relentless pursuit of excellence in the realm of multilayer PCB applications. With unrivaled thermal capabilities and exceptional electrical performance, FR408HR empowers designers and manufacturers to transcend limitations and achieve unparalleled results. Its compliance with industry standards and global availability solidify its position as the ultimate choice for those seeking reliability and performance in their electronic designs. Choose FR408HR, and unlock a world of limitless possibilities in the realm of PCBs.

Quality Policy

Bicheng has developed series of management procedures and approaches to assure that PCBs are in compliance with the customers' requirements, inclusive of selection of the vendors, work in progress (WIP) inspection, outgoing delivery inspection and customer service etc.

Evaluation and Audit of Suppliers

Suppliers have to be evaluated by Bicheng. In addition, Bicheng will appraise and rank suppliers every year to guarantee the materials supplied are meeting Bicheng’s requirements. Furthermore, Bicheng continuously develop suppliers and supervise them to improve their quality and environment management basing on the systems of ISO9001 & ISO14001.

Contract Evaluation

Bicheng shall review and verify customer's requirements to make sure that we have the capability to satisfy customers' requirements including specifications, delivery and other demands prior to accepting an order.

Making, audit and control of manufacturing data.

When customers' design data and specifications are provided to our market department, Bicheng has to verify all the requirements. Then, convert the design data into manufacturing data by CAM. Finally, a manufacturing instruction (MI) is generated according to the real manufacturing process and technologies for manufacturing department as the basis for actual fabrication. MI must be reviewed by independent engineers and QA engineers before issue.

Incoming Material Quality Control

All materials have to be inspected before warehousing. We established a series of strict inspection procedure and instruction to control the incoming materials. Furthermore, various precise inspecting instruments and apparatus guarantee the capability to judge the material good or not. We issue material with first in first out principle, and give out “alarm” for the material that will reach the shelf life to ensure the materials are used up before expiry.

Control of Production Process

Right manufacturing instruction (MI), comprehensive equipment management and maintenance and process control, strict WIP inspection and monitoring as well as working instruction, all those make the whole fabrication process totally controlled.

Final Control and Inspection

All PCBs have to be gone through the open and short test as well as visual inspection after passed the specified physical tests. We own various advanced test equipment including customized, probe flying test machines to guarantee that each PCB is 100% tested.

Product Delivery Audit

We set up a dedicated FQA department to inspect the PCB products according to the customer's specifications and requirements by sampling. Qualified PCBs are going to be packed.

FQA also has to carry out a 100% audit of the warehouse packing and shipping products, including product number, customer number, product quantity, shipping address and so on prior to shipment.

Customer Service

We sets up a professional customer service team to proactively communicate with customers and timely deal with the customers' feedbacks. We highly focus on customers' needs and to understand customers’ demands, timely to adjust the policy of customer service and PCB product requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!